Setting Ignition Timing

Setting ignition timing on cars today is usually not required. I still own 2 timing lights and find it necessary to adjust the engines timing on rare occasions. This is only possible on vehicles that still have distributor type ignitions.

Although most vehicles nowadays have direct ignition my 2004 Chevrolet Blazer with a 4.3 L V-6 engine still has a distributor and you can adjust base timing. Remember only engines equipped with a distributor may need to have their ignition timing set or adjusted.

Although the computer still controls ignition timing on distributor ignition, having the base timing correct is critical for proper performance and fuel economy. If the base timing setting is wrong the advance curve settings can also be wrong.

On modern vehicles with distributor type ignition the timing is advanced as RPM increase. These controls are the function of the computer and the curve is not adjustable. To set the base timing there will be different procedures to follow to disconnect the computer from the distributor so that the setting can be adjusted.

Procedures for Setting Ignition Timing

Each vehicle manufacturer will have slightly different versions of ignition systems deployed on their vehicles you should always refer to an auto repair manual and also take a look at your emissions service label that is usually mounted on the radiator support.

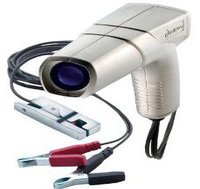

In some cases the emissions service label will provide a procedure for disabling the computer’s control of the timing so that proper reading and adjustments can be made. Some advanced scan tools are able to take a reading of the ignition base timing. When you disconnect the distributor to make adjustments that will no longer function. This is why a timing light is still needed for this operation.

To check the base timing a strobe light is aimed at the ignition timing marks. Timing marks are usually located on the crankshaft pulley but in some cases can be located on the flywheel side of the crankshaft. Again you’ll have to check your service manual to find out not only what your base timing settings should be but also where the timing marks are located.

Usually an engine is timed so the number one spark-plug fires several degrees before the piston reaches top dead center. When the timing light is connected to the number one spark plug wire and will flash every time this wire is fired. When pointed at the timing marks it may look like a strobe light that will actually freeze the spinning timing marks as it passes the scale so that your eyes can detect it. Yes it’s like a disco club.

Problems with Setting Ignition Timing

It is important to remember that most computerized and spark control systems will use some type of knock sensor to retard the ignition timing when ping occurs. Engine ping is also known as incorrect detonation. This is really important on today’s modern aluminum engines.

In some cases when the cylinder detonates at the wrong time extreme temperatures can be the result. These temperatures can be extreme enough to melt aluminum cast engines. This is why the knock sensor will automatically retard the timing and attempt to stop the detonation and prevent engine damage.

Messing around with your cars engine timing should only be attempted if you have done some research about the procedure and have some do-it-yourself driveway mechanic skills. When in doubt take the vehicle into your local auto repair shop and have this procedure performed by professional.

I hope that you found this article helpful even if you decide not to attempt to adjust your own ignition timing. Knowing more about the subject can usually be helpful in either dealing with your auto repair shop or identifying that there is a problem to be addressed. I have a few more articles about this subject on the auto repair information blog.